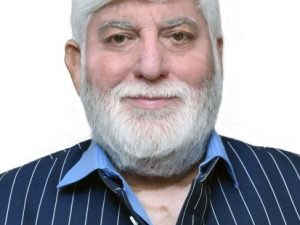

Rajen Bhatia, Director, Tulsidas Khimji, India, Chairman, Western Region, The Air Cargo Agents Association of India (ACAAI) said, “The government’s focus on upgrading infrastructure and warehousing for air cargo, especially for perishables and agricultural products, will significantly boost air cargo growth. Improved cold chain facilities and faster airport processing will enhance efficiency, reduce turnaround times, and ensure product quality. Specialised infrastructure for high-value goods will open up global markets, while better logistics support e-commerce growth. Investments in modern warehousing and technology will reduce logistics costs and improve inventory management. This initiative will streamline operations, increase capacity, and attract more private sector participation, ultimately fostering a more efficient and dynamic air cargo sector.”

Read More »DTDC unveils new facility in Bengaluru for same day e-com deliveries

DTDC has entered rapid commerce space by launching 2–4-hour rapid delivery and same-day delivery services. This expansion is a testament to DTDC’s ability to leverage its robust logistics network, cutting-edge technology, and its success in the domestic e-commerce sector to enhance last-mile delivery solutions for businesses and consumers alike. As part of this strategic move, DTDC has established its first Dark Store in Bengaluru, signaling the beginning of a hyperlocal fulfillment ecosystem that will significantly improve the speed and efficiency of last-mile deliveries. This initiative will empower D2C brands and social commerce sellers, enabling them to provide rapid and efficient delivery services across India. DTDC plans to expand this service making rapid delivery options available to businesses and customers nationwide. This expansion will further solidify DTDC’s role in transforming the logistics and e-commerce landscape by meeting the growing demand for rapid delivery in today’s fast-paced digital world.

Read More »DP World’s ports handle 88.3 mn TEUs in 2024, up 8.3 % YOY

DP World’s ports and terminals handled a record 88.3 million twenty-foot equivalent units (TEUs) in 2024, up 8.3 per cent year-on-year, despite macroeconomic headwinds and concerns over the outlook for global trade. The global logistics business, which now has the capacity to handle more than 100 million TEU across operations in 78 countries, benefitted from long-term infrastructure investment contributing to strong growth and new services calling at its terminals. While the Red Sea crisis posed a significant challenge to global shipping in 2024, causing delays and rerouting across major trade corridors, DP World’s record performance underscores the strength of its diversified global portfolio and its ability to navigate supply chain volatility, ensuring continued service for customers worldwide. Sultan Ahmed bin Sulayem, Group Chairman and Chief Executive Officer of DP World, said, “During the last 10 years we have invested more than $11 billion in world-class ports and logistics infrastructure to make trade flow. This record performance is further evidence that our long-term investment is providing the right services for our customers in the right places. “As we continue to expand our reach deeper into the global supply chain by expanding our end-to-end logistics capabilities, we are confident that the container market will continue to grow and that we have the capacity to service it. Whatever the short-term challenges, we remain bullish on the outlook for world trade.”

Read More »‘Strong push for infrastructure upgradation & warehousing essential’

Vipin Vohra, Chairman, Continental Carriers said, “The government’s strong push for infrastructure upgradation and warehousing development, particularly for air cargo, high-value perishables, and agriproducts, is a game-changer. The latest Union Budget’s emphasis on infrastructure development, regulatory improvements, and enhanced connectivity reflects a strategic vision to transform India into a global aviation leader. These advancements will drive economic growth, improve supply chain efficiencies, and position India as a key global aviation hub by 2030, boosting exports and competitiveness.”

Read More »‘Govt will support domestic industries for leveraging export opportunities’

Sunil Kohli, MD, Rahat Cargo said, “The Budget has proposed several steps to promote agri and perishable products under ‘Prime Minister Dhan-Dhaanya Krishi Yojana’ in partnership with states covering 100 districts to increase productivity, adopt crop diversification, augment post-harvest storage, improve irrigation facilities, and facilitate availability of long-term and short-term credit. The Budget has outlined measures to Comprehensive Programme for Vegetables & Fruits, National Mission on High Yielding Seeds. The government will facilitate upgradation of infrastructure and warehousing for air cargo including high value perishable horticulture produce. The Finance Minister mentioned that support will be provided to develop domestic manufacturing capacities for our economy’s integration with global supply chains. She also announced that government will support the domestic industries for leveraging the opportunities related to export fraternity. Every effort will also be made by the government to upgrade the infrastructural facilities at the airports to promote exports.

Read More »‘Increased capital allocation for modernising warehousing, cargo screening will enhance efficiency’

Reshma Zaheer, CEO, TT Logistics & Cargo and President, ACFI Women’s wing said, “The Indian government’s focus in the Union Budget 2025 on upgrading air cargo infrastructure, particularly for perishables and agricultural products, is a welcome step. It acknowledges air cargo’s crucial role in economic development and trade competitiveness. Increased capital allocation for modernizing warehousing, streamlining customs, and improving cargo screening will enhance efficiency, reduce clearance times, and support the movement of goods. These efforts will foster sector growth and help achieve the ambitious target of handling 10 million tonnes of air cargo by 2030.

Read More »‘Enhanced cold chain infra, customs will reduce transit time & improve exports’

Arun Kumar, President, AMTOI said, “The Indian government’s focus on upgrading air cargo infrastructure and warehousing, especially for high-value perishables and agri-products, will significantly boost air cargo growth. Enhanced cold chain facilities, modernised cargo terminals, and streamlined customs processes will reduce transit time, minimise wastage, and improve global market access for Indian exports. Initiatives like Krishi Udan and improved multimodal connectivity will further drive volumes, making India a competitive hub for agri and perishable exports, strengthening overall air cargo demand in the coming months.”

Read More »‘Strategic investments in air cargo facilities must to support & expand trade’

Kamal Jain, Director, Cargomen Logistics said, “Air cargo is the fastest mode of transportation and is primarily used in scenarios where goods are urgently required, have a short shelf life, or require rapid economic value realisation. This makes it the ideal choice for perishable goods, be it high value pharma perishable or fruits and vegetables, where timely delivery is crucial to maintain quality and prevent spoilage. Government investment in air cargo infrastructure plays a significant role in boosting cargo movement and throughput. By developing better infrastructure for the storage and movement of perishable cargo, we can facilitate trade of such goods. This, in turn, leads to a rise in air cargo movement and contributes to the overall growth of the air cargo sector. Without adequate infrastructure, trade in perishable products remains limited. Therefore, strategic investments in air cargo facilities are essential to support and expand the trade of perishable commodities like fruits and vegetables, ultimately driving the development and growth of the air cargo industry.

Read More »CargoAi, CMA CGM join forces to enhance cargo bookings

CargoAi announced a strategic partnership with CMA CGM Air Cargo, a division of CMA CGM Group to enhance airfreight booking capabilities on CargoMART, CargoAi’s cutting-edge platform for freight management, by integrating CMA CGM AIR CARGO’s extensive network across their network. Following a successful testing period, CMA CGM Air Cargo will now extend its digital booking capabilities to include CargoAi as one of its partners. This partnership will provide freight forwarders with a seamless, efficient booking experience and access to a comprehensive network of routes. Matt Petot, CEO of CargoAi, expressed his enthusiasm about the new partnership: “We are delighted to collaborate with CMA CGM AIR CARGO, a prominent leader in the air cargo industry. This partnership highlights our dedication to providing best-in-class digital solutions that optimize operations and drive efficiency in the air cargo sector.” CargoMART provides a range of features including real-time capacity and rate visibility, quoting, e-Booking, and Track and Trace functionalities. One differentiating feature of the platform is the ability to compare flight options by carbon emissions, track CO2 emissions at a shipment level, and purchase sustainable aviation fuel (SAF) whenever required. With the integration of CMA CGM AIR CARGO’s network and products, CargoMART users will benefit from more options and enhanced booking flexibility when booking capacity that meets their needs. Following the integration, CMA CGM AIR CARGO will have exposure to more than 17,000 freight forwarders across more than 130 countries who regularly use the CargoAi marketplace. This partnership between CargoAi and CMA CGM AIR CARGO represents a mutual dedication to innovation and excellence in airfreight services, further solidifying their position as leaders in the industry.

Read More »‘Increased capital allocation for air cargo infra will boost connectivity’

Vipin Vohra, Chairman, Continental Carriers says, “The Union Budget 2025-26 charts an ambitious course for growth while maintaining fiscal responsibility, with a strong focus on the logistics, air cargo, and supply chain sectors. Increased capital allocation for air cargo infrastructure in emerging industrial regions will strengthen connectivity with global trade routes, while upgraded warehousing and streamlined customs protocols will enhance cargo handling, particularly for high-value perishable goods. To equip the workforce for the future, five National Centres of Excellence will be established for skill development. Support for domestic manufacturing will be reinforced through facilitation groups comprising industry and government representatives. The introduction of BharatTradeNet (BTN) as a unified trade documentation and financing platform will complement the Unified Logistics Interface Platform (ULIP), enhancing digital integration. • Additionally, a ₹25,000 crore Maritime Development Fund will promote competitiveness in global ocean trade. • Recognizing the success of UDAN, the government will expand regional connectivity by linking 120 new destinations, operationalizing helipads and smaller airports, and targeting 4 crore passengers over the next decade. Through strategic collaboration between the government and industry stakeholders, these initiatives will drive efficiency, modernization, and transformative growth in India’s logistics and air cargo sectors.

Read More » Cargo Breaking News

Cargo Breaking News